With the upsurge of school opening for students across the country, our "students" of WAP, under the leadership of Mr. Wang and Mr. Ni, resumed their studies, started the learning motor, and gave professional explanations from the company introduction, factory tour route, equipment brand and function. And practical operation, at the same time, Mr. Wang asked all technical quality personnel to raise two levels to look at the problem, conduct professional training in two aspects: car light/rearview mirror structure and vehicle installation sheet metal structure, and contact the 4S shop for actual vehicle assembly learning and drill!For the exciting content, please refer to the company introduction below and the explanations of each workshop in the factory. Mr. Ni requires the management personnel of all administrative departments of the company to go to the production workshop to learn, and to find problems by finding faults with all employees.What is its purpose?It is to let everyone experience the working environment of the direct department operators and how to carry out their work; it is to be familiar with the production situation of each workshop of the enterprise, and to understand the equipment, production process and management process of each workshop of the enterprise.Through on-site learning in the workshop, we can discover cognitive blind spots, learn to discover and solve problems, and at the same time improve cognitive ability and management personnel's ideological understanding, unite people's hearts, and inspire everyone to do their jobs better.

Dismantling of headlights and rearview mirrors and training for loading

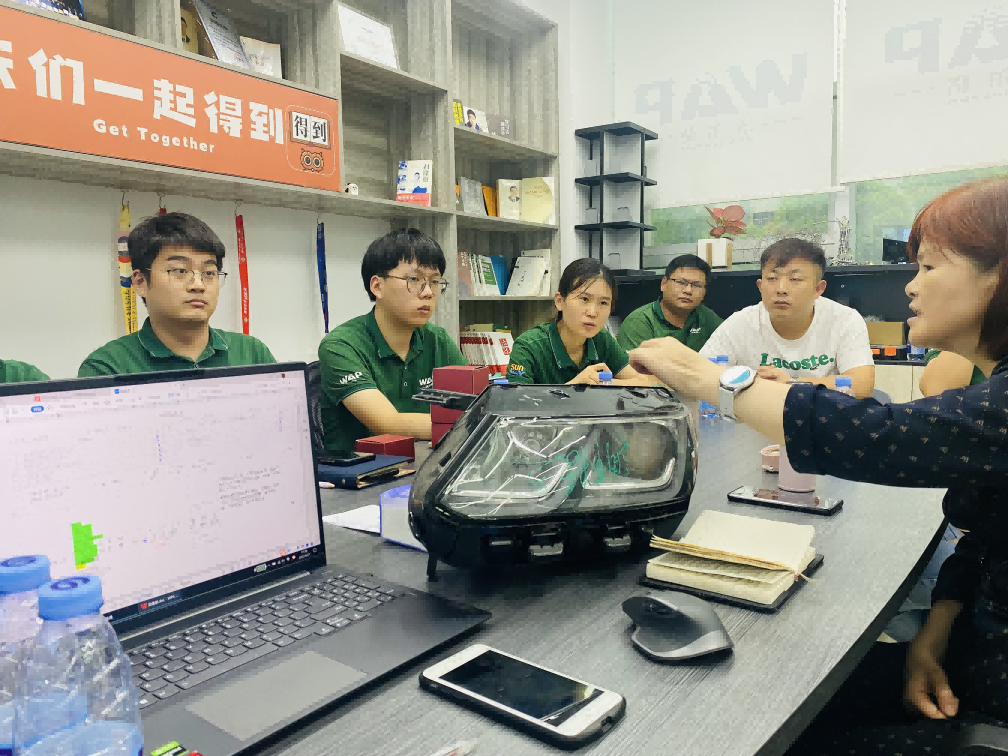

Mr. Wang explained and trained according to the dimming structure of mainstream car lights and the real objects of rearview mirror turn signal fasteners, and made a comprehensive theoretical foundation for loading cars in 4S shops;

When I arrived at the 4S store, my colleagues carefully observed and discussed the matching structure of the car lights, rearview mirrors and cars. Under the explanation of the 4S store technician and Mr. Ni, the following effects were achieved: 1. Through the ideal LED headlight Dismantle and install to understand the technical requirements and matching status of the thick-walled parts and dimming components of the car lights; 2. By dismantling the Chevrolet taillights, understand the internal structure of the taillights and the connection method and key role of the fasteners with the body to strengthen quality Awareness; 3. By repeatedly dismantling the rearview mirror, learn the role and importance of fastening bolts and side turn signals on the vehicle.Production quality management system training Of course, as an excellent supporting supplier, it is not enough to only understand the installation and matching of products and customer products. Without perfect quality system management, product consistency and quality stability cannot be guaranteed. , President Wang conducted special training on the internal audit clauses of the quality management system to ensure that all departments can sort out and implement the work of their own departments according to the internal audit checklist.